|

|

| The Muncie 4-speed

transmission was used with many different GM models and engine

combinations from 1963 through 1974. The basic design and

operation theory of the gearbox changed little during this

period, however several design upgrades and modifications were

made during the total production run. The Muncie was used with

most performance engines, and is not to be confused with the

Saginaw or Borg Warner 4-speeds. |

|

|

The Muncie is distinguished from the Saginaw in that

the reverse lever on the Muncie is mounted in the extension

housing, where the Saginaw reverse lever is mounted in the

side cover. The main difference between the Muncie and the

Borg-Warner is that the Muncie has a 7-bolt side cover and the

Borg Warner has a 9-bolt side

cover. | |

|

|

|

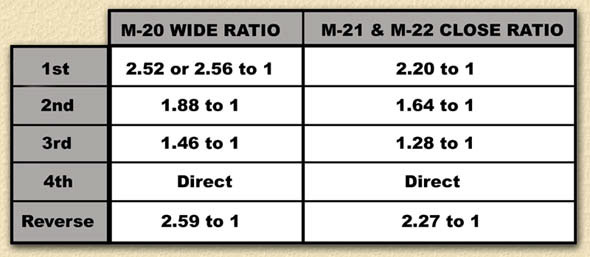

Muncie 4-speeds were produced in two different ratios

wide ratio (M-20) and close-ratio (M-21). An extra heavy duty

close-ratio version (M-22) was also offered on many of the

big-block high-performance models.The choice of transmission

was dictated by the engine size and rear-axle ratio. Axle

ratios of 3.73 and lower (numerically higher) came with

close-ratio transmissions, while axle ratios of 3.55 and

higher (numerically lower) used wide-ratio transmissions. In

addition, many GM high-performance engines came with M-22

“Rock-Crusher” in the 1970-73 years, however an early version

of the M-22 was available as early as 1965 in

Corvettes. |

Proper identification of the transmission type is

absolutely necessary, but sometimes difficult due to several

factors. First, GM used several different methods to label and

identify transmissions from year to year and model to model.

Unfortunately the identification systems seem to have many

exceptions, rendering them virtually useless to the restorer.

In addition, due to engine and transmission swaps, and

modifications that occur over the years many cars do not carry

the original drivetrain that they were produced

with.

For example, due to interchangeability, a 1969

Pontiac could have a trans case and gears from a Buick and a

rear housing (extension) from an Oldsmobile. Several

production changes through the years that effect the external

appearance may also cause additional confusion when

identifying a particular transmission:

1. Both

single and dual drain plugs were used.

2. Speedometer

adapters were used on either sides of the rear section

(extension).

3. Side covers were sometimes secured with

studs and nuts, other times with bolts.

4. Input shafts may

be fine or coarse spline. Output shafts may be large or small.

Combinations of these vary.

5. External shift levers are

secured with studs and nuts, others with bolts. Some levers

are long and some short.

6. Input shafts may have 1 ring, 2

rings, or no rings at

all. | |

|

M-22 “Rock Crusher”

Identification

The M-22

close-ratio transmission is easily identified internally from

the M-20 and M-21 versions by the angle of the gear

teeth.

The M-22 was only produced in a close-ratio

version, so it will not appear on models with high rear-axle

ratios (3.55 or lower numerically) unless someone has changed

it.

The main internal differences in the 3 types of

transmissions are listed in the parts below.

• M-20 differs

from M-21: Input shaft and Cluster gear

• M-20 & M-21

differ from M-22: Input shaft, Cluster gear, First, Second,

Third, Reverse idler gear

All other components

interchange, with the exception of production upgrades and

changes. For example, 1963-65 synchronizers, blocking rings,

etc. do not interchange with 1966 and newer versions, and

therefore the transmission must be stock or interchanged as a

unit.

|

M-20

Wide Ratio

Cluster gear

teeth: 25-22-19-17

Input shaft/gear teeth:

21

M-21

& M-22 Close-Ratio Cluster Gear teeth:

27-22-19-17

Input shaft/gear teeth: 26

|

|

IMPORTANT |

If you have any questions, please contact

Year One. Call them

before ordering.

To ensure that you are ordering the correct parts for your

transmission, please carefully count the number of teeth on

all gears and or counter gears (clusters) to verify

transmission type. We recommend that all transmission parts be

ordered by telephone to verify requirements and reduce the

chance of ordering errors. We also recommend installation of

all parts by trained professionals with the proper tools and

equipment. If you are rebuilding your transmission yourself,

be sure to use a factory service manual.

| |

|

|

|